"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

10/16/2017 at 12:00 • Filed to: Saab 900, project, wrenching

8

8

1

1

"Urambo Tauro" (urambotauro)

"Urambo Tauro" (urambotauro)

10/16/2017 at 12:00 • Filed to: Saab 900, project, wrenching |  8 8

|  1 1 |

Made some more progress on the 900.

Information on the fuel sender was hard to come by, but a close look at the terminals and where they go suggested that the broken wire was likely for a low fuel lamp. And the resistance readings that were coming out of testing this one showed that this one worked in the opposite manner that the sender on the new pump assembly did.

So we carefully cleaned the bottom of the sender, revealing a push nut that allowed us to disassemble the cylinder. The other blue wire broke off during handling, but we kept track of where everything went and managed to solder it all back together. After cleaning and reassembling, we plugged the sender into the car (sans tank) and confirmed operation. Sure enough, there was a low fuel lamp on the dashboard.

Moving on to the fuel filter, it would not come off without a fight. It had to be locked in a vise to loosen a particularly rusty banjo fitting, which we ended up replacing along with its rounded-off bolt.

This meant that to remove it from the car, we had to cut off the tip of the nylon tubing. But there was not enough flex in the line to accommodate easily installing the new one, so a coupler and some fresh nylon tubing were needed to line it back up again.

Next, we removed the fuel rail. Again, we had a stubborn banjo bolt, but not nearly as rusty, and certainly salvageable. We then blew some compressed air through the rail and the fuel lines to confirm that they were clear. I was half-tempted to hook up an old fuel pump that came off of my truck, and use it to cycle some mineral spirits or something through the lines, but TBH they seemed amply clear enough already.

We removed the injectors, too. After seeing that mess in the fuel tank, we feared the worst here, as these tiny passages seemed extra-vulnerable to clogging. So we popped all four of them out, and looked up !!!error: Indecipherable SUB-paragraph formatting!!! for DIY injector cleaning.

Instead of tapping one of the leads against a battery to cycle the injector on and off, we just used the on/off dial of my jump-box. As for the straw adapter, I just so happened to have the perfect size rubber hose to firmly slide over the top of the injector, as well as some vacuum tubing that was slightly bigger than the straw. I probably didn’t even need to use any heat-shrink, as the ear clamp that I used instead of a hose clamp pinched the hose VERY tightly around the straw. But I think the heat-shrink still helped as a stress-relief for the straw anyway.

My brother clicked the power on and off to work the injector, while I sprayed carb cleaner through. We got the timing wrong a couple of times, blowing the straw clean off of the can, but the homemade adapter held together like a boss. In short time, all 4 injectors ran clear with good spray patterns, and we treated them to new O-rings and pintle caps.

The new fuel pump had arrived, a direct replacement for the one that came out of the tank. Still not sure if the old one was original or not, as the float arm and resistor was totally unnecessary with the standalone sending unit. I can’t imagine why Saab would bother to install a second sender that wouldn’t even work with the car.

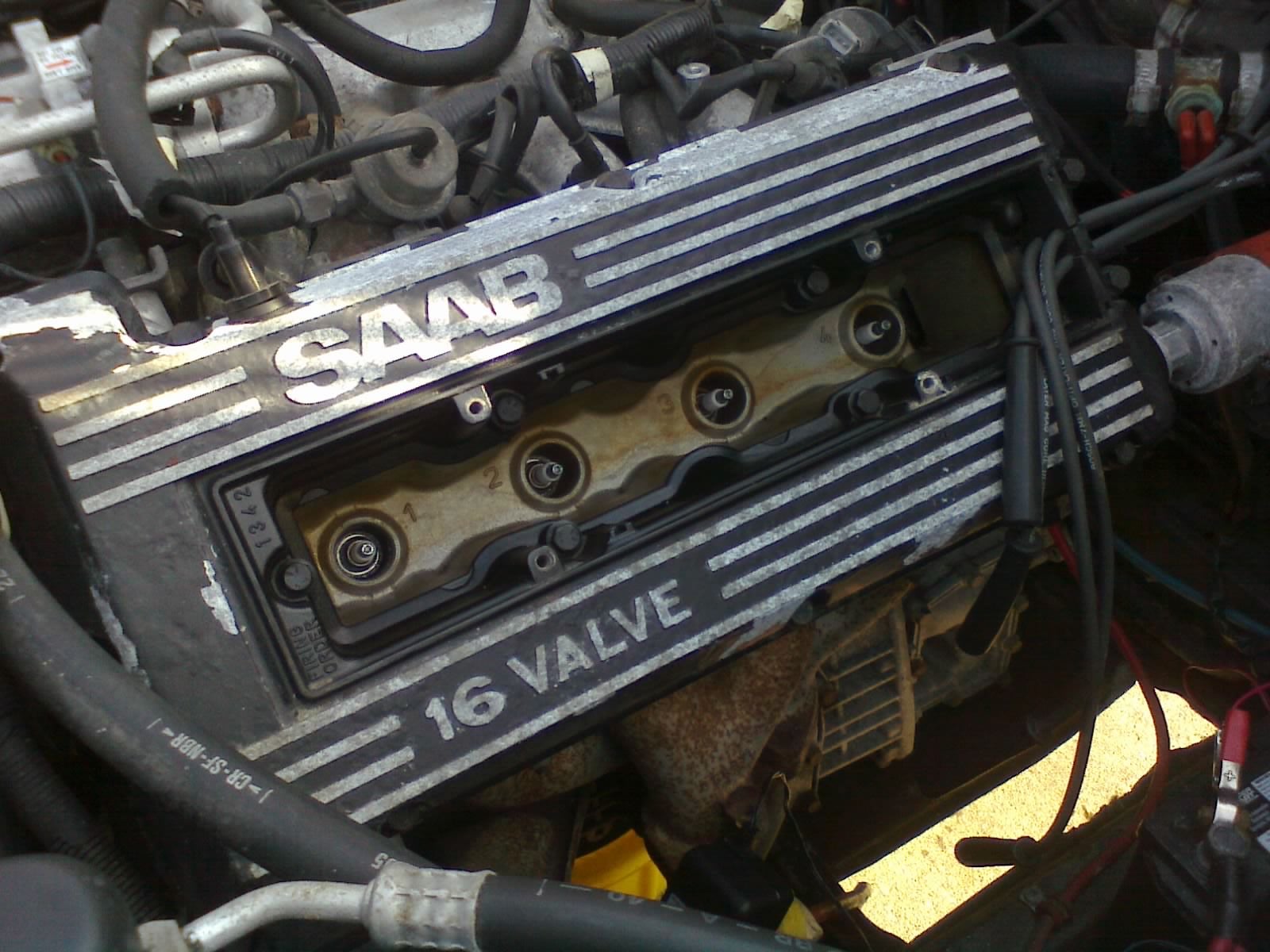

To make installation a little easier, we removed the float arm from the new pump assembly and continued to work on cleaning the tank out. While it dried, we decided to prep the engine by changing the oil + filter for the first time in well over a decade, and pulling the spark plugs to clean or replace.

Working backwards from the date and mileage posted on the oil change sticker, we estimate a typical 3-month, 3000-mile service interval, which would indicate that the oil was last changed in November 2004, and that the car had been driven a total of 611 more miles before being parked at Ron’s.

Somebody had tightened the piss out of the old filter, compressing the gasket about as much as it would go. Even my toothed filter pliers started to slip. But I managed to finally spin it off, and we made sure that the new one was properly tightened (and lubricated!).

Finally, we pulled the spark plugs. They’re copper-core, and it wouldn’t cost much to replace them, but to avoid another run to the parts store, we just cleaned them up and re-gapped them.

Next is to reassemble the tank with the pump and sender in it back into the car and put some gas in it. The car ran on ether, so I have no doubt that it will soon be able to fire up under its own power and run for more than just a few seconds.

How will it run? Will it overheat? Does it leak anywhere? I can’t wait to find out.

Steve in Manhattan

> Urambo Tauro

Steve in Manhattan

> Urambo Tauro

10/16/2017 at 12:42 |

|

Nice!

Will post photos of old 9000 I saw this morning.